A regular maintenance inspection of turbines on a business jet makes it possible to anticipate the risks of breakage and accidents.

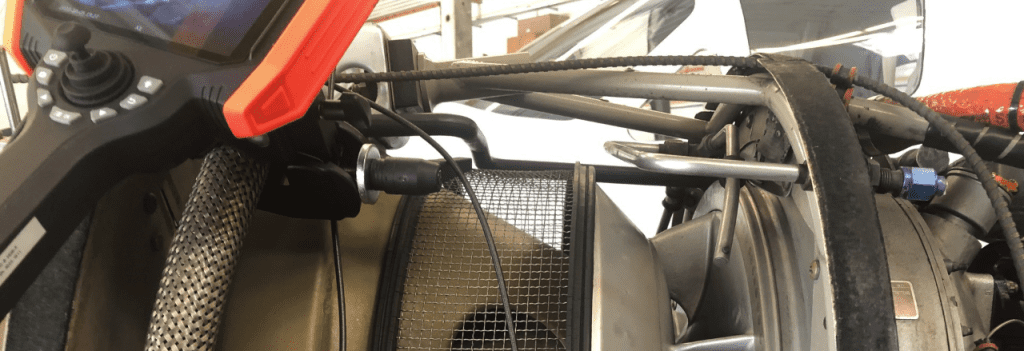

On this Piper Cheyenne airplane, Mr Gauliard checked the different parts of the turbine including the blades and the reducer in order to ensure its integrity and its proper functioning (without costly dismantling it).

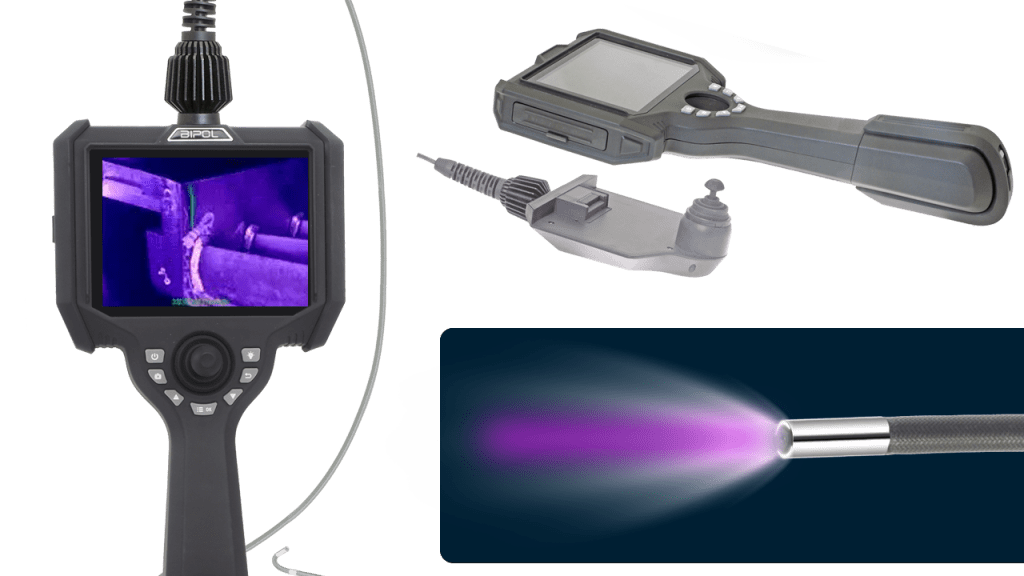

The high resolution of our videoscope (1,000,000 px), its large 5" screen and its dedicated accessories made it possible to carry out a complete inspection of the various control points in only 2 hours.

- The hot parts of the turbine

- Reduction gears

- The different parts of the blades (fir-tree blade roots, blade and plate)

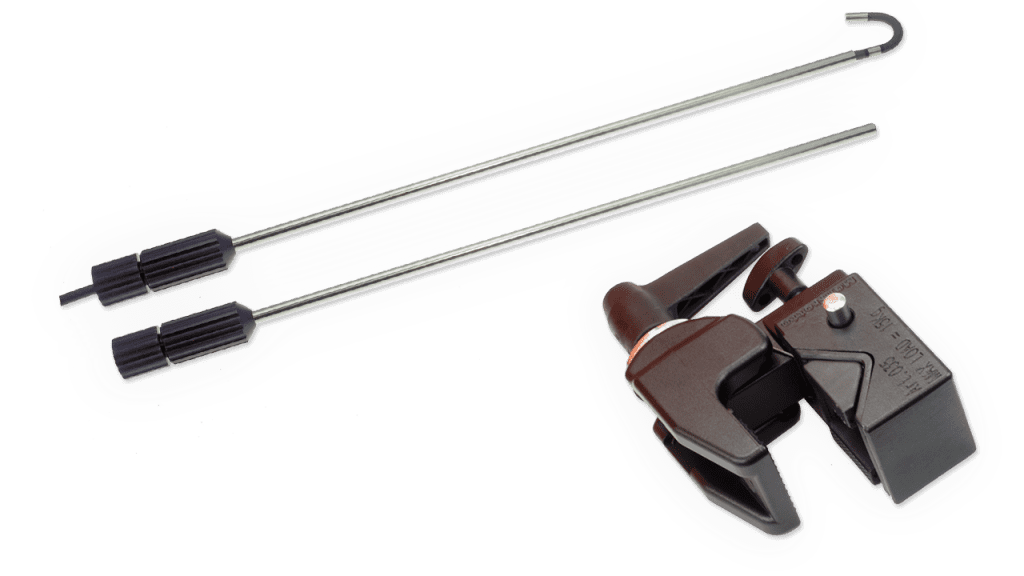

The AA kit consists of our PRO-B-3920-F videoscope with direct vision 0° and accessories to perform a safe and precise inspection. We deliver a Ø6.0mm rigid guide as well as a clamp allowing the videoscope to be hung on any square or round tube up to a diameter of 55mm.

The videoscope is also compatible with the original PT6 guide tubes.

It has been certified for prior inspection on the CFM LEAP-1A engine by INAC (Portuguese Instituto Nacional de Aviaçáo Civil) via the LAS company.

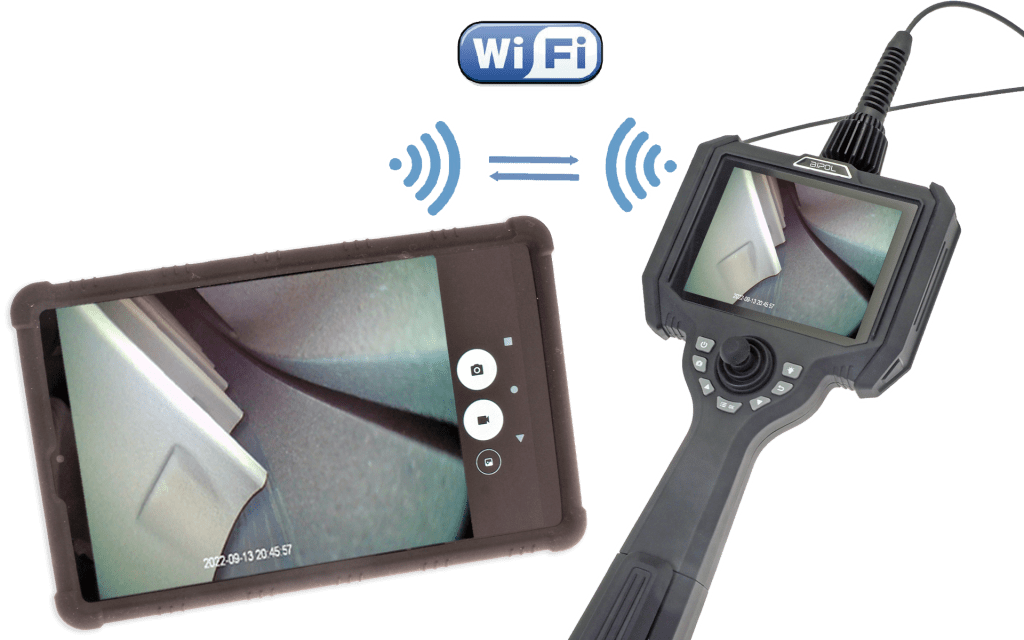

Wi-Fi app

Share your live inspection of turbines with your colleagues up to a distance of 20 meters thanks to the Wi-Fi function of our videoscope compatible with Android devices via a dedicated Bipol application.

To go further in your NDT inspections.

When in doubt about the integrity of a part or the need for costly aircraft disassembly and grounding, we offer additional inspection tools to help you refine your analysis.

We thus offer:

Our videoscope with 3D measurement PROC-X

UV video probes (365 Nm) compatible with the PRO B videoscope.

We would like to thank Mr Stephan Gauliard for his excellent shots and for his help in the development of our kit.