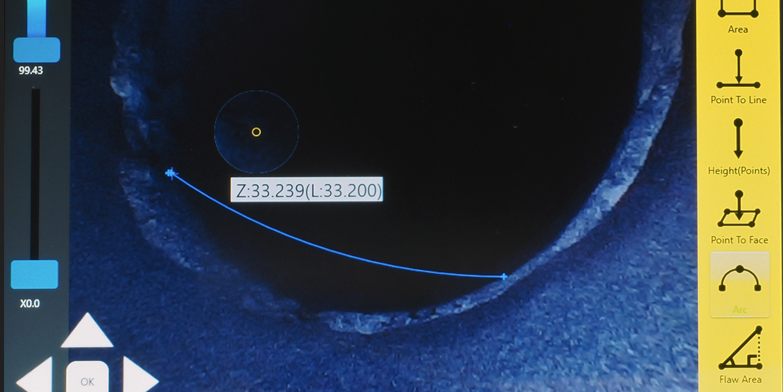

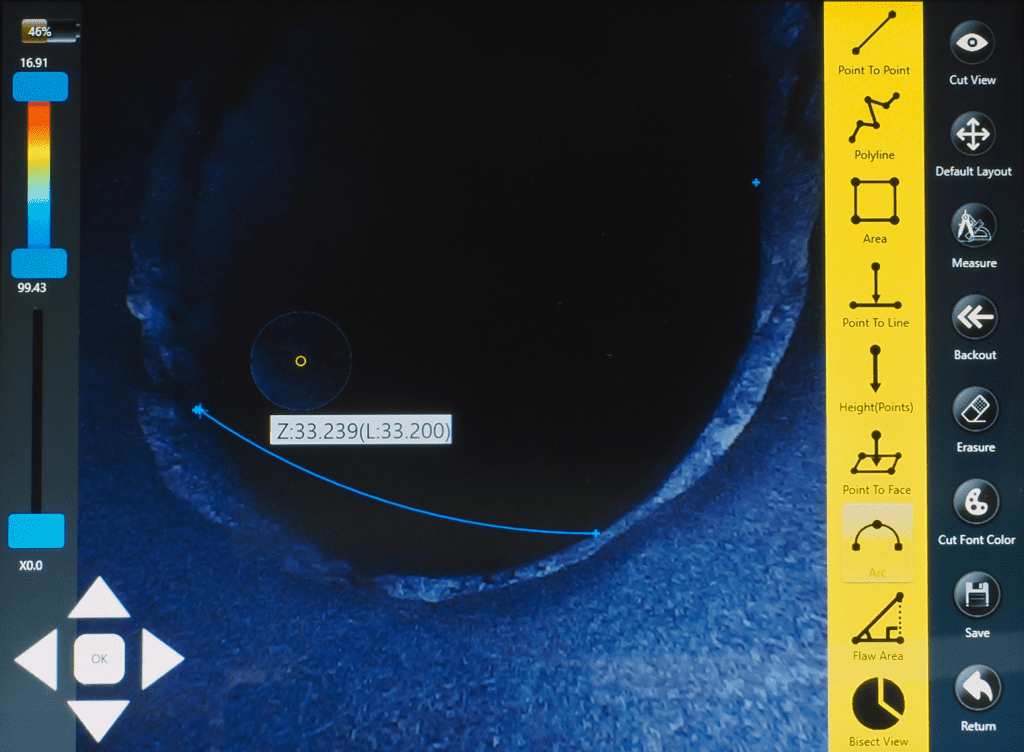

The 3D stereoscopic measurement function represents a major step forward in visual inspection technology. This measurement method enables a detailed assessment of anomalies and imperfections while preserving the integrity of the observed components. It is particularly valuable in industries where the early detection of defects is critical to prevent costly or hazardous failures. Whether inspecting aircraft engines, turbine components, or mechanical parts in the automotive, energy, or maritime sectors, 3D inspection via video borescope has become an indispensable tool for professionals seeking precise, rapid, and non-invasive analysis.

What advantages?

- High precision and comprehensive measurement capabilities: This technology enables accurate calculations of length, width, surface area, and depth of defects such as cracks on internal components, all performed directly on-site.

- Time-efficient and non-invasive: This fast, non-destructive method enables detailed inspections without dismantling components, reducing machine downtime and minimising risks of damage while preserving the integrity of the parts.

- Proactive maintenance and fault prevention: By detecting anomalies early, it allows for targeted maintenance planning and proactive measures to prevent failures, helping to avoid high repair costs and unexpected production halts.

- Improved safety and operational efficiency: Early identification of cracks and defects enhances equipment and infrastructure safety, while extending the lifespan and improving the performance of machines, particularly in key sectors such as aerospace and energy.

Which sectors benefit from it?

- Aerospace

In aviation, the 3D stereoscopic measurement function plays a vital role in inspecting and evaluating critical components such as turbine blades and combustion chambers. This technology not only identifies cracks and signs of corrosion but also provides precise calculations of their size and depth. By enabling technicians to monitor wear progression more effectively, it supports informed decisions on the urgency of interventions, ensuring both operational safety and enhanced engine reliability.

- Oil and Gas Industry

In the oil and gas sector, this function is essential for inspecting pipelines, welds, and storage tanks. By accurately measuring crack depth and the extent of corrosion, it enables technicians to make informed decisions on preventive maintenance. Taking action before issues such as leaks occur enhances both operational safety and efficiency.

- Automotive

In the automotive industry, 3D stereoscopic measurement is invaluable for evaluating internal components such as engines, cylinders, and gearboxes. This technology provides precise measurements of micro-cracks and wear, allowing technicians to assess the severity of damage and prioritise maintenance tasks effectively, helping to prevent costly breakdowns.

- Energy and Civil Engineering

In power plants, wind turbines, and other critical infrastructure, the 3D stereoscopic function is vital for inspecting equipment such as turbines and generators. By precisely calculating the depth of cracks and the extent of mechanical wear, it enables maintenance teams to plan repairs effectively based on the actual condition of components. This approach ensures both operational continuity and safety.

- Maritime

In the maritime sector, 3D stereoscopic measurement is essential for inspecting propellers, gears, and propulsion systems. This advanced technology delivers precise measurements of damage caused by cavitation or wear, providing technicians with a detailed evaluation. This enables them to determine if immediate intervention is required before the next operation.

Conclusion

In summary, videoscopes with stereoscopic measurement functionality, such as our PRO GX M, provide the crucial precision needed to identify and monitor defect progression, allowing for the effective prioritisation of interventions. This advanced technology enhances safety, streamlines maintenance, reduces costs, and prolongs equipment lifespan.

To learn more about our PRO GX M videoscope and its stereoscopic measurement function, click here.